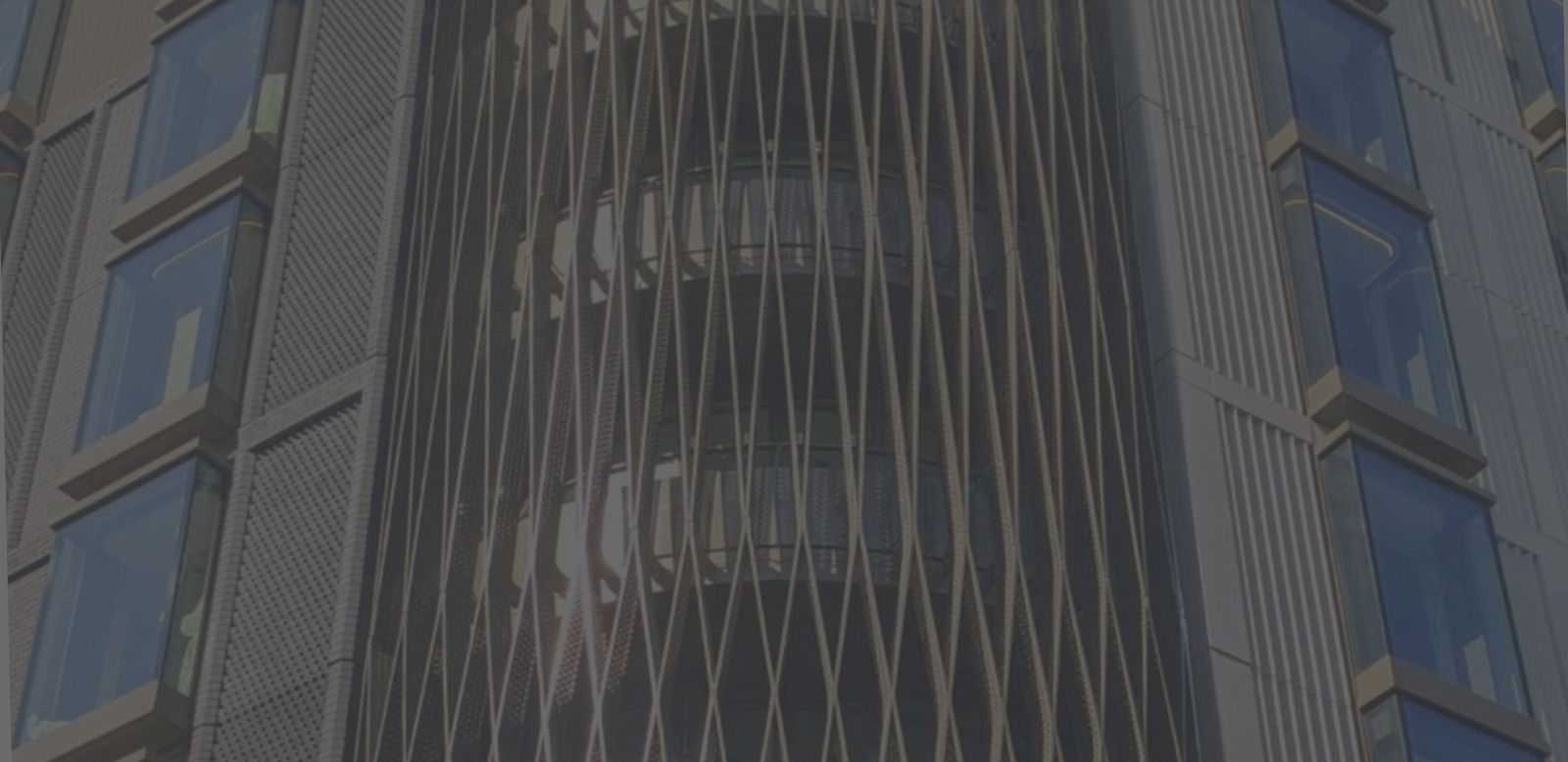

Facade design expertise to support coordinated, compliant and buildable solutions.

We provide engineering input throughout design development, from early concept through to technical design. This includes coordinating structural, thermal, fire and acoustic considerations, resolving key interfaces and ensuring the facade design progresses in a compliant and buildable direction.

Our team prepares concept and detailed facade drawings to support design coordination, planning submissions and technical development. These drawings outline proposed systems, interfaces, fixing approaches and performance requirements to help guide the wider design team.

We provide the technical documentation and engineering inputs needed to support Gateway 2 submissions, helping ensure the external wall design demonstrates the necessary safety, compliance and performance before construction begins.

We undertake performance assessments for proposed cladding systems, reviewing aspects including fire performance, thermal efficiency, water management, structural capacity and compatibility of components. Our findings are presented in clear, actionable reports to support decision-making.

We develop technical performance specifications that define the required behaviour, durability and compliance of the facade systems. This covers areas such as weather resistance, thermal performance, fire behaviour, acoustics, movement, tolerances and material requirements.

The facade technical performance specification shall comply with all applicable Building Regulations, British/ European Standards, best practice guidance and CWCT recommendations.

During the PCSA phase, we support the refinement of cladding designs, review contractor proposals and assist with tendering to ensure submissions meet technical, safety and programme requirements.

We advise on visual mock-ups, benchmarking panels and full-scale performance mock-ups to confirm build quality, design intent and technical behaviour. Our involvement helps teams verify detailing, interfaces, materials and construction methods before site installation.

We carry out factory inspections for cladding contractors to review fabrication quality, processes, tolerances and compliance with the project specification. Findings are summarised in clear reports to support quality assurance.

We also inspect material suppliers’ facilities to confirm product quality, certification, handling methods and production consistency. This helps reduce risk in supply chains and supports confidence in the materials being used.